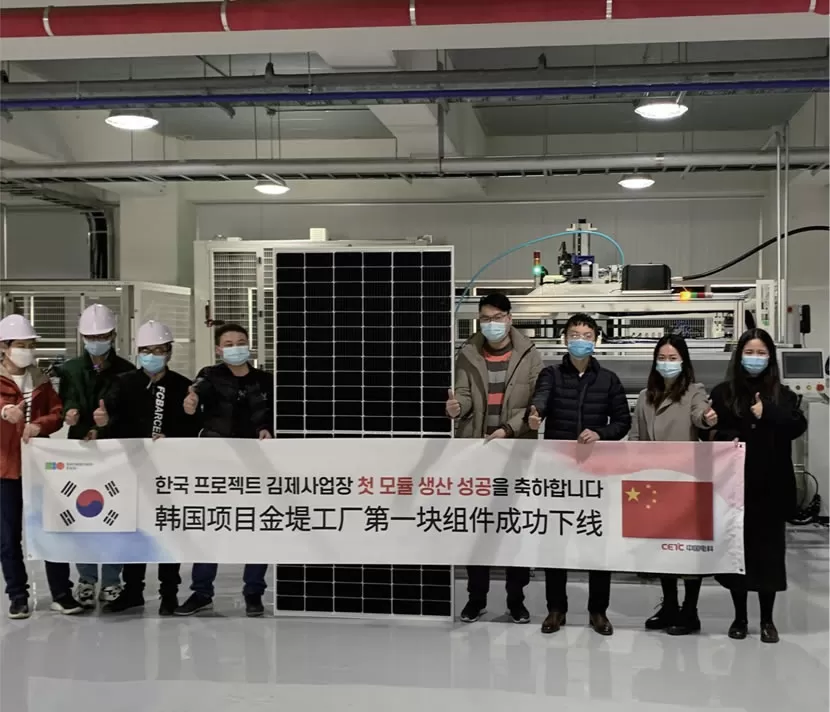

First PV Module Successfully Produced at Gimje Plant in Korea

The construction of a solar PV module production line at the Gimje plant in Korea is an important part of the SMM project, which aims to promote regional economic development and renewable energy utilization, and to demonstrate Korea's leadership in green energy technology and international cooperation by creating an onshore solar power project to provide clean energy for the Northeast Asian economic center.

I. Project Background and Objectives

Against the backdrop of global energy structure transformation, Korea is actively responding to the goal of “carbon neutrality” and has made the photovoltaic industry a core area of green economic development. Located in Jeollabuk-do, Korea, the Gimje plant plans to build a high-efficiency solar module production line with an annual production capacity of 1.2GW, relying on local policy support and location advantages, with the goal of becoming a benchmark project for intelligent, low-carbon PV manufacturing in the Asia-Pacific region.

The project signed a 600MW module production line construction contract in July 2020, and started production line installation and commissioning work at the project site in South Korea from October, and completed acceptance by the end of February 2021.

Ⅱ.Construction program and core technology

1. Intelligent production line design

The project adopts the “automation + digitalization” dual-wheel drive mode, equipped with fully automatic string welding machine, laminating machine, EL detector and other equipment, to achieve unmanned operation of the whole process of module production, and increase production efficiency by more than 30%. The production line is compatible with 182mm and 210mm large-size wafers, and supports double-sided power generation, half-chip and multi-master grid technologies, with a module conversion efficiency of 21.8%.

2. Low-carbon process optimization

Utilizing material innovation technology, applying ultra-thin glass, environmentally friendly backsheets and lead-free welding tapes to reduce the carbon footprint of modules.

Reasonable energy management, integrated photovoltaic roof and energy storage system, realizing 50% self-sufficiency of green power in the plant.

3. Plant Planning and Facilities

The plant adopts integrated steel structure design, divided into raw material storage area, production workshop, quality inspection center and R&D laboratory, equipped with intelligent logistics AGV system to realize efficient material flow.

III. Implementation Effectiveness and Experience

1. Economic Benefits

The total investment of the project is about 250 million U.S. dollars, and the annual output value is expected to exceed 360 million U.S. dollars after reaching production, with a payback period of 4.2 years and a financial internal rate of return (IRR) of 18.5%.

2. Technological breakthrough

The self-developed “high-speed and low-loss string welding process” controls the fragmentation rate below 0.1%, and has been certified as a green technology by Korea.

3. Social Benefits

The project drives local employment of more than 800 people, and improves the skill level of industrial workers through technical training, forming a regional PV industry cluster effect.

IV. Summary and Prospect

The Gimje plant has become a benchmark for the Korean PV manufacturing industry through intelligent production lines, low-carbon processes and refined operations. In the future, it plans to expand into the research and development of heterojunction (HJT) modules to further consolidate its competitiveness in the global PV industry chain.

One step to find us,we will respond within 24 hours.

More Contact Details

008613738639386

[email protected]