Installation of solar photovoltaic panels

If the world is consuming energy very fast, there is a large demand for solar PV projects all over the world, and all are looking for PV projects that are suitable for their region. And nowadays, the PV industry technology is updated very fast, how should we pick the right PV project for ourselves? Well first of all, you have to understand the core technology of solar photovoltaic cells before you can really find the right PV project for you.

Crystalline silicon cell technology framework and manufacturing process

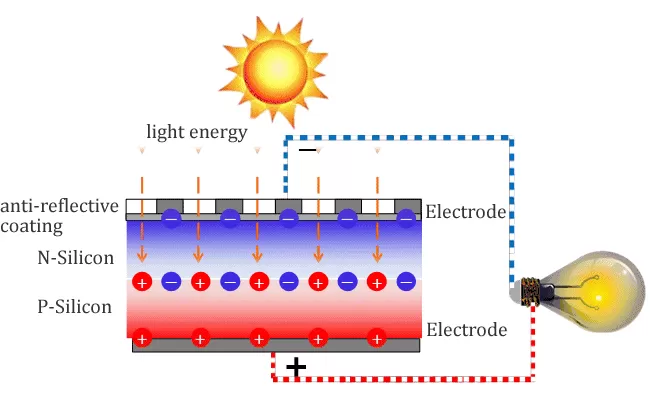

Solar Photovoltaic Conversion Principle

At present, the solar photovoltaic cell technology is dominated by the crystalline silicon route, and its manufacturing process contains four core aspects:

1. Fleece Cleaning

Through chemical corrosion to remove impurities and damage layer on the surface of silicon wafers, and form micron-level pyramid velvet structure, which can reduce the incident light reflectivity to less than 10%. The plasma etching equipment developed by Wuxi Pilot Intelligence optimizes the reflectivity of single crystal silicon to 7.3%, which is 23% higher than the traditional process.

2. Diffusion junction

To form P-N junction on the surface of silicon wafer, the mainstream process adopts phosphorus diffusion method. The low-pressure diffusion technology developed by Orient Sunrise makes the uniformity of P-type monocrystalline silicon square resistance reach ±3Ω, and the efficiency of the cell is increased by 0.15%. N-type TOPCon cell adopts the boron diffusion technology, and the uniformity of the square resistance breaks through ±1.5Ω, and the yield of mass production reaches 98.6%.

3. Passivation Coating

Passivation layer is formed by atomic layer deposition (ALD) or plasma enhanced chemical vapor deposition (PECVD). LONGi Green Energy's HPBC technology adopts double-layer SiOx/SiNx composite film, the surface compounding rate is reduced to less than 50cm/s, and the open-circuit voltage breaks through 740mV. The amorphous silicon/nano-crystalline silicon stacked passivation technology of HJT battery reduces the interfacial state density to 1×10¹⁰/cm², and the double-sided rate exceeds 95%.

4. Metallization process

Silver paste screen printing is still the mainstream, but silver-coated copper, copper plating technology to accelerate the penetration. The 18BB multi-master grid technology developed by TONGWEI has reduced the silver paste unit consumption to 12mg/W, and the grid resistance loss to 0.15Ω-cm².

Solar Photovoltaic Crystalline Silicon Cells

PV Technology Iteration and Efficiency Breakthrough

1. Laboratory Efficiency Record

U.S. NREL-certified chalcogenide/crystalline silicon stacked cell efficiency reached 33.9%, a 38% improvement over single-junction cells. Trina Solar's self-developed 210mm-sized HJT cells reached 26.5% efficiency in mass production, with module power exceeding 750W.

2. Economy of mass production technology

The production cost of granular silicon of GCL Technology has been reduced to 35,000 yuan/ton, and the carbon footprint value has been reduced by 74% compared with that of Siemens method. The 12-inch single-crystal furnace developed by Shuangliang Energy Conservation makes the thickness of silicon wafers reduced to 130μm, and the silicon consumption reduced to 1.8g/W.

Typical application cases and technology verification in PV industry

1. 200MW photovoltaic power plant in Ningxia, China

Adopting bifacial PERC modules + intelligent tracking bracket, the measured power generation in 2024 reaches 380 million kWh, which is 19% higher than the fixed bracket system. The module attenuation rate is 0.45%/year, which is lower than the industry's 1% guarantee value.

2. Yancheng 2GW offshore PV

The world's largest floating photovoltaic power station application 182mm TOPCon module, measured water surface cooling effect makes the module working temperature reduced by 8-12 ℃, system efficiency increased by 3.2%. The project LCOE is as low as 0.25 yuan/kWh, 15% lower than that of onshore power station.

Development trend of photovoltaic technology

1. Metallization Innovation

Today's silver paste substitution technology accelerated development, 2024 silver-coated copper paste has realized 30% silver content under the contact resistance <3mΩ-cm², is expected to 2026 industry silver consumption will be reduced to 8mg/W.

2. Cascade technology breakthrough

LONGi Green Energy's pilot line of calcite/crystalline silicon triple-junction stacked cell went into production, with a theoretical efficiency limit of 45%. The key TCO transparent conductive film transmittance > 93%, square resistance <15Ω.

3. Smart Manufacturing Upgrade

JinkoSolar constructed the industry's first 5G fully-connected factory, which enables the EL hidden crack identification accuracy to reach 99.98% and the fragmentation rate to be reduced to 0.03% through AI visual inspection.

Clarify the application scenarios of PV projects

1. Installation environment assessment

Rooftop projects are prioritized to use lightweight double-glass modules (≤18kg/m²) to reduce loading requirements, and water projects need to use floating bracket system + anti-PID modules (attenuation rate <0.5%/year).25 Ground-based power stations are recommended to be equipped with single-axis tracking brackets, which can enhance power generation by 15-20%.

2. Energy Demand Calculation

Commercial and industrial projects need to maximize the self-generation and self-consumption rate (>85%) by configuring ≥30% energy storage capacity in combination with peak and valley tariffs. Household system is calculated according to the average daily power consumption of 20kWh, it is recommended to install 8-10kW system to match the bidirectional meter.

Battery technology route selection criteria

1. Battery technology comparison

PERC battery: system cost 3.2-3.5 yuan RMB / W as a benchmark, suitable for projects with limited budget, mass production efficiency of 24.5%.

TOPCon battery: system cost 3.5-3.8 yuan RMB / W) as a benchmark, medium and high investment is preferred, mass production efficiency of 26.2 percent

HJT battery: preferred in high irradiation areas with double-sided rate >95%, system efficiency gain of 8%.

2. Component Specification Adaptation

Distributed projects prefer 182mm/210mm large-size modules with a power of 650W or more, reducing BOS costs by 10-15%. In high latitude areas over 40°, it is recommended to use bifacial modules + 1.2 times overmatching design.

Photovoltaic Energy Storage Systems

View Economic Analysis Model

1. Return on Investment Measurement

Using LCOE (Levelized Cost of Electricity) model, the LCOE of mainstream projects in 2025 has been reduced to RMB 0.22-0.28/kWh. focus on:

Silver paste consumption <15mg/W

Wafer thickness ≤130μm

Equipment depreciation cycle > 8 years

2. Financial Program Options

Priority is given to the “self-generation and self-consumption + surplus power on-grid” model, with an IRR of 12-15%.

Technology Verification and Implementation Guarantee

1. Evaluation of enterprise's technical strength

Focus on enterprise mass production battery efficiency (PERC ≥24.2%, TOPCon ≥25.8%), intelligent manufacturing level (fragmentation rate <0.05%) and number of patents (>2000 patents for TOP3 manufacturers).

2. Operation and maintenance system construction

Select service providers equipped with IV curve scanning diagnosis (fault recognition rate >98%) and drone inspection (inspection efficiency increased by 20 times) to ensure that the system availability rate is >99%.

Summarize

Through the above analysis of the core technology of solar photovoltaic cells and case studies, we can combine the above photovoltaic applications and analysis, to find the right method for their project parameters, such as assessing the return on investment from a corporate perspective, analyzing the financial solutions from the operation and maintenance system structure, etc., and even in the type of family or small factories, to find the right type of batteries and storage for their own and so on. Whether you start your analysis from solar panels or start thinking about PV storage systems, you can find the most suitable solution for your PV project on the Brice Solar website.

One step to find us,we will respond within 24 hours.

More Contact Details

008613738639386

[email protected]