With the accelerated global energy transition, the photovoltaic industry has become a crucial pillar of renewable energy development. In recent years, global photovoltaic installed capacity has increased by as much as 85% year-on-year, with China accounting for more than 60% of the global new installed capacity, highlighting its leading market position. Against this backdrop, the selection of photovoltaic power plant products, including photovoltaic modules, inverters, mounting systems, and auxiliary equipment, directly affects the power generation efficiency, operational reliability, and overall life-cycle economic benefits of the power plant. A scientific selection strategy needs to comprehensively consider initial investment, operation and maintenance costs, and long-term returns, taking into account the specific climate, terrain, and policy constraints of the scenario, and choosing the solution with high technical adaptability and the optimal cost per kilowatt-hour.

1. Photovoltaic Module Selection

1.1 Quality and Durability Requirements

Photovoltaic modules are exposed to the outdoor environment for extended periods. Therefore, products using high-quality materials and possessing good sealing and waterproof performance should be prioritized to ensure normal operation under harsh weather conditions. The durability of the modules directly affects the lifespan of the power plant. When selecting modules, attention should be paid to manufacturing processes, material quality, and anti-aging performance, choosing well-known brands that have been proven in the market.

1.2 Comparison of Technology Types and Economic Efficiency

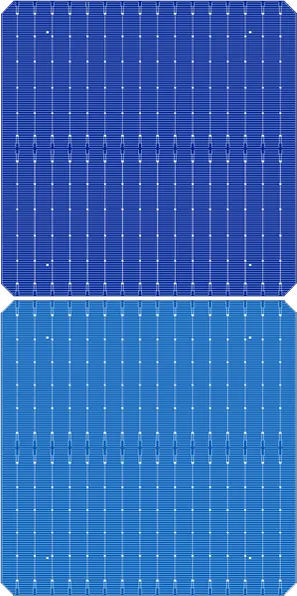

Monocrystalline silicon solar cells possess a complete crystal structure, resulting in low electron mobility resistance, high conversion efficiency, and excellent low-light performance. They can better utilize sunlight for power generation on cloudy days or in low-light conditions, and have a lifespan of 25-30 years. N-type TOPCon modules have a bifaciality exceeding 80%, significant low-temperature gain, and an annual power generation increase of 2.87% compared to PERC technology, making them particularly suitable for high-latitude, cold regions. While IBC modules offer excellent low-light response, they suffer from low bifaciality and insufficient back-side gain.

Large-scale power plant selection should prioritize Levelized Cost of Electricity (LCOE). Taking projects in Inner Mongolia as an example, 210mm 660Wp modules offer a cost advantage over 182mm 540Wp modules in terms of support structures, foundations, and cables, resulting in a lower LCOE over a 20-year operating cycle.

Distributed power project selection should consider the differences in roof type. Small residential applications prioritize increasing installed capacity; large residential and small-to-medium-sized commercial and industrial applications need to balance area and capacity; large commercial and industrial applications focus on cost reduction through high-power, high-efficiency modules.

1.3 Temperature Coefficient and Environmental Adaptability

The temperature coefficient of a module affects its performance at different temperatures. In low-temperature regions (i.e., daily temperatures not exceeding 25°C), high temperature coefficient modules (such as PERC) should be prioritized, while in high-temperature regions, low temperature coefficient modules (such as TOPCon) should be selected to reduce temperature rise losses.

2. Inverter Selection

2.1 Performance Indicator Focus

Inverter selection must ensure that the output power matches the photovoltaic modules, and products with high conversion efficiency should be selected to reduce energy losses. String inverters use a multi-MPPT design, which can effectively reduce module mismatch losses, and the power generation efficiency is 1.7% higher than that of centralized inverters. Its low-load efficiency should reach above 97.5%, and overload capacity and heat dissipation performance should be emphasized to prevent capacity limitations due to dust filter blockage or excessive temperature.

2.2 Grid Compatibility Requirements

Inverters should possess low-voltage ride-through capability and good power quality to ensure efficient parallel operation with the grid. MPPT tracking accuracy directly affects the system's maximum power point tracking performance; selecting inverters with strong MPPT tracking capability can significantly improve power generation efficiency.

3. Support System Selection

Support system selection requires a comprehensive consideration of power generation gain and cost-effectiveness. Single-axis supports are the preferred choice for most scenarios due to their lowest levelized cost of electricity (LCOE); dual-axis supports generate more power but have higher maintenance costs, making them suitable for high-electricity-price regions with excellent irradiance; flexible supports are more adaptable to complex terrains, but structural stability needs to be strengthened to cope with wind load risks.

4. Auxiliary Equipment Selection Standards

4.1 Cable Selection

Conductors with good conductivity (such as copper or aluminum) and insulation materials with strong weather resistance and high temperature resistance should be selected. Choosing appropriate cable cross-sections based on current magnitude and laying method can effectively reduce voltage drop and line loss.

4.2 Transformer and DC Combiner Box

The transformer capacity must match the output power of the photovoltaic array. Self-cooling or air-cooling methods should be selected to ensure effective heat dissipation. The maximum current of the DC combiner box should be greater than the maximum output current of the photovoltaic modules, and products with lightning protection should be selected to improve system safety.

5. Selection Methodology and Empirical Verification

5.1 Comprehensive Consideration Principle

The selection of photovoltaic power station products must strictly adhere to Chinese national standards such as the "Design Code for Photovoltaic Power Stations" (GB50797-2012). Simultaneously, the impact of environmental factors such as light intensity, temperature, and humidity on equipment performance must be comprehensively considered.

5.2 Empirical Data Support

The cold-temperate high-latitude photovoltaic energy storage demonstration platform established by State Power Investment Corporation in Daqing, Heilongjiang Province, has verified the reliability and economy of modules, inverters, and support structures under extreme climate conditions through 640 experimental schemes. Empirical experimental data is an important basis for selection. Verifying the deviation between equipment performance and theoretical design through actual operation ensures that the selected scheme combines reliability and economy. By comparing key indicators such as component back-side gain, inverter dynamic response, and bracket failure rate, a scientific basis is provided for product selection.

Conclusion

Selecting photovoltaic (PV) power plant products is a multi-objective optimization process that requires a comprehensive consideration of technical performance, environmental adaptability, and total lifecycle cost. In the context of rapid technological iteration, selection decisions should place greater emphasis on empirical data support, combining specific project scenarios to choose a product combination with high technological maturity, strong reliability, and the optimal levelized cost of electricity, thereby maximizing the economic and environmental benefits of PV power plants.

One step to find us,we will respond within 24 hours.

More Contact Details

008613738639386

[email protected]