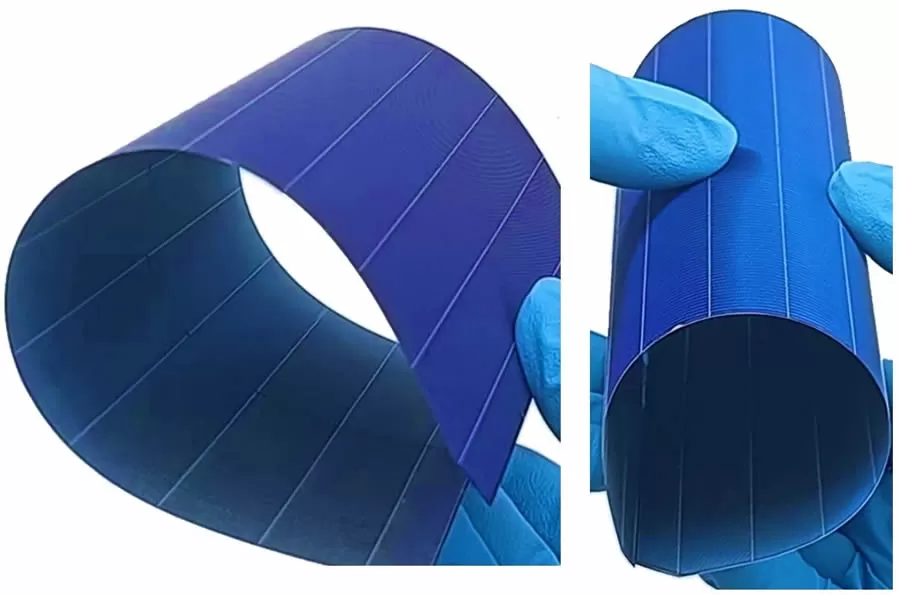

Bendable Ultra-thin Thin Film Solar Cells

Under the background of accelerated transformation of the global energy structure, and with the continuous breakthrough and innovation of solar photovoltaic power generation technology, crystalline silicon cells as the dominant photovoltaic market and thin-film batteries with differentiated advantages are forming an industrial pattern of technological complementarities and competition, etc. Brice Solar will introduce the technical characteristics and commercial value of the two major crystalline silicon and thin-film battery technology routes, namely crystalline silicon cells and thin-film batteries, from the perspectives of material science, industrialization process, and typical application scenarios. Brice Solar will introduce the technical characteristics and commercial value of the two major crystalline silicon and thin-film cell technologies from the dimensions of material science and industrialization process and typical application scenarios.

1.1 Crystalline Silicon Modules and Dual Junction Silicon Based Thin Film Modules

1.1 Introduction to Crystalline Silicon Modules (Polycrystalline Silicon)

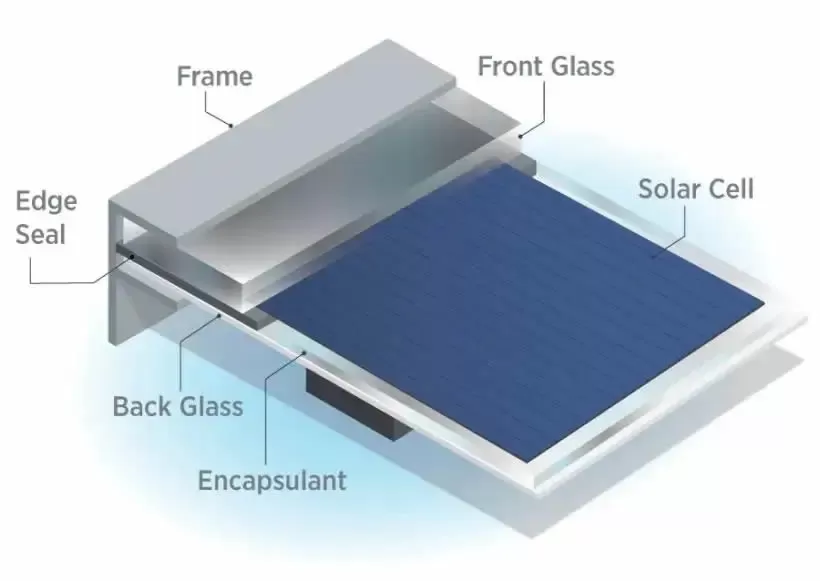

Polycrystalline silicon photovoltaic modules are composed of glass, EVA, cells, backsheets and panels, etc.). Because of its reasonable price and good performance, polycrystalline silicon module occupies a relatively large share of the market.

The current conversion efficiency of polycrystalline silicon modules is about 15%, which is slightly lower than monocrystalline silicon products, but higher than amorphous silicon module conversion efficiency. Polycrystalline silicon cells do not have photocatalytic recession effect, a slight difference in material quality will not lead to solar cells affected. However, polycrystalline silicon cells single piece of power there is a certain degree of variability, the same area of the power of the module well there is a certain difference (usually there is a difference of 20Wp-30Wp). Another advantage of polycrystalline silicon cell is that it can obtain high and stable power generation performance per unit area. The current nominal lifetime of polycrystalline silicon modules is 25 years.

1.2 Introduction to Bi-Junction Silicon Based Thin Film Modules

Silicon is currently the dominant material in solar cells, and amorphous silicon solar cells use about one percent of the silicon material used in crystalline silicon cells, which greatly reduces the cost of raw materials. A double-junction silicon-based thin-film module is composed of a glass substrate, a transparent conductive layer, and a semiconductor layer (as shown in Figure 3). Dual-junction silicon-based thin-film modules can be used in building-integrated applications, rooftops, and large-scale ground-mounted power plants. At present, the laboratory conversion efficiency of double-junction silicon-based thin-film modules reaches 15%, and the efficiency after mass production is about 10%.

2、Technology principle and industry status

2.1 Crystalline silicon batteries: benchmark for industrial maturity

Polycrystalline Solar Cells

Crystalline silicon batteries to the P-N junction photovoltaic effect of silicon-based semiconductor materials as the core, the technology iteration through three key stages:

P-type battery era: the traditional aluminum back field (BSF) battery efficiency ceiling of 20.3%, after 2016 PERC technology through the back passivation will be raised to 23.5% efficiency, market share once more than 85%.

N-type technology breakthroughs: TOPCon cells achieve selective carrier transport by tunneling through the oxide layer, laboratory efficiency exceeded 26%, Trina Solar, JinkoSolar and other companies have achieved 25.8% mass production efficiency; HJT cells use amorphous silicon/crystalline silicon heterojunction structure, and Maiwei's promotion of the 120 μm ultra-thin wafer technology makes the cost continue to dip.

Advanced packaging technology: SMBB (multi-master grid) and no-master grid technology will increase module power by 5-8%, and N-type double-glass modules with double-sided rate exceeding 85% have become the standard for large-scale power stations.

2.2 Thin-film Battery: Technology Breakthrough in Differentiated Tracks

High-efficiency ultra-thin film solar cell structure

Thin-film batteries are prepared by vapor deposition technology on glass, flexible substrate micron-sized photovoltaic layer, the core route includes:

Cadmium telluride (CdTe): First Solar achieves module efficiency of 19.6% by virtue of continuous vapor phase transport deposition (VTD) technology, with a single production line having an annual capacity of 3.3GW, and the manufacturing cost is reduced to USD0.25/W.

Copper indium gallium selenide (CIGS): Hanergy Group developed the co-evaporation process to make the conversion efficiency exceeded 17.7%, and the power-to-weight ratio of flexible modules reached 400W/kg, which is suitable for BIPV curved buildings.

Chalcogenide: GCL Optoelectronics has built a production line with an annual output of 100MW chalcogenide modules, achieving a stable efficiency of 18.5% through solution coating technology, with a theoretical limit efficiency of 33%.

3、Performance parameters and cost comparison

|

Indicators |

Crystalline Silicon Cells (N-Type TOPCon) |

CdTe Thin Film Cells |

CIGS Thin Film Cells |

|

Lab Efficiency |

26.8% |

22.1% |

23.4% |

|

Mass Production Module Efficiency |

22.5%-23.8% |

18.5%-19.6% |

16.5%-17.7% |

|

Temperature coefficient(%/℃) |

-0.30 |

-0.25 |

-0.35 |

|

Low light response(200W/m²) |

85% power rating |

92% power rating |

88% rated power |

|

Production Cost ($/W) |

0.18-0.22 |

0.25-0.28 |

0.30-0.35 |

|

Energy payback period (years) |

1.2-1.5 |

0.8-1.0 |

1.0-1.3 |

Data Analysis

Thin-film cells have a significant advantage in high-temperature performance and low-light power generation. Tests at the Arizona Desert Power Station in the U.S. show that CdTe modules generate 12% more power than PERC modules on a single day in the summer. But crystalline silicon in the supply chain maturity occupies an absolute advantage, 2023 global silicon production capacity of more than 1.3 million tons, supporting the annual output of 400GW components.

4. Typical application scenarios and business cases

4.1 Crystalline silicon dominated field

Large-scale ground power station: Saudi Arabia NEOM 2.2GW project adopts double-sided N-type modules, with LCOE as low as 1.04 cents/kWh.

Distributed PV: LONGi's Hi-MO 7 series modules occupy 65% of the household market with 23.2% efficiency and 30-year warranty.

Offshore PV: Dongfang Electric used anti-PID (Potential Induced Degradation) N-type modules in Shandong Piled Offshore Power Station, with annual degradation <0.5% under salt spray corrosive environment.

4.2 Thin film technology breakthrough direction

BIPV building integration: Tesla Solar Roof V4 adopts CIGS flexible modules, with roof coverage increased to 95% and power generation capacity of 180W per square meter.

Mobile energy: CNBM constructed the world's first 100MW CdTe power generation glass production line, and the products are applied to the curtain wall of Xiongan high-speed railway station, with an annual power generation capacity of 5.8 million degrees.

Space photovoltaic: NASA tested chalcogenide/crystalline silicon stacked batteries in Lunar Gateway lunar space station, the efficiency exceeded 34.2%, and the radiation attenuation rate is only 1/3 of traditional batteries.

5. Technology Convergence and Future Trends

5.1 Stacked Battery Technology

Oxford PV deposits a layer of chalcocite on the surface of HJT batteries, realizing a certified efficiency of 31.3%, with a module power density exceeding 400W/m², and the mass production cost is expected to drop to $0.35/W in 2025.

5.2 Silicon-based thin film hybrid technology

Hanwha Qcells develops Q.ANTUM Neo technology, integrating amorphous silicon passivation layer on the surface of TOPCon cells, with double-sided rate increased to 90% and system PR (performance ratio) increased by 3.8 percentage points.

5.3 Intelligent Manufacturing Upgrade

JA Solar's Ningjin base has built an Industry 4.0 smart factory, and the AI vision inspection system has increased the EL hidden crack detection rate to 99.97% and reduced the fragmentation rate to 0.08%.

6、Conclusion and Recommendation

Crystalline silicon technology will still dominate the mainstream market in the next 5-8 years by virtue of its mature supply chain and continuous innovation; the technical economy of thin film batteries in specific scenarios has been verified and can be focused on the following points:

Power stations in high latitude areas prioritize CdTe modules to enhance winter power generation;

Commercial and industrial rooftop projects adopt lightweight CIGS modules to reduce structural modification costs;

R&D organizations can layout next-generation technologies such as chalcogenide/crystalline silicon stacked cells;

The diversified development of solar PV technology is building a more efficient energy future, and the choice of technology routes needs to be combined with application scenarios, whole-life costs, high-quality photovoltaic application solutions and sustainable development goals.

One step to find us,we will respond within 24 hours.

More Contact Details

008613738639386

[email protected]