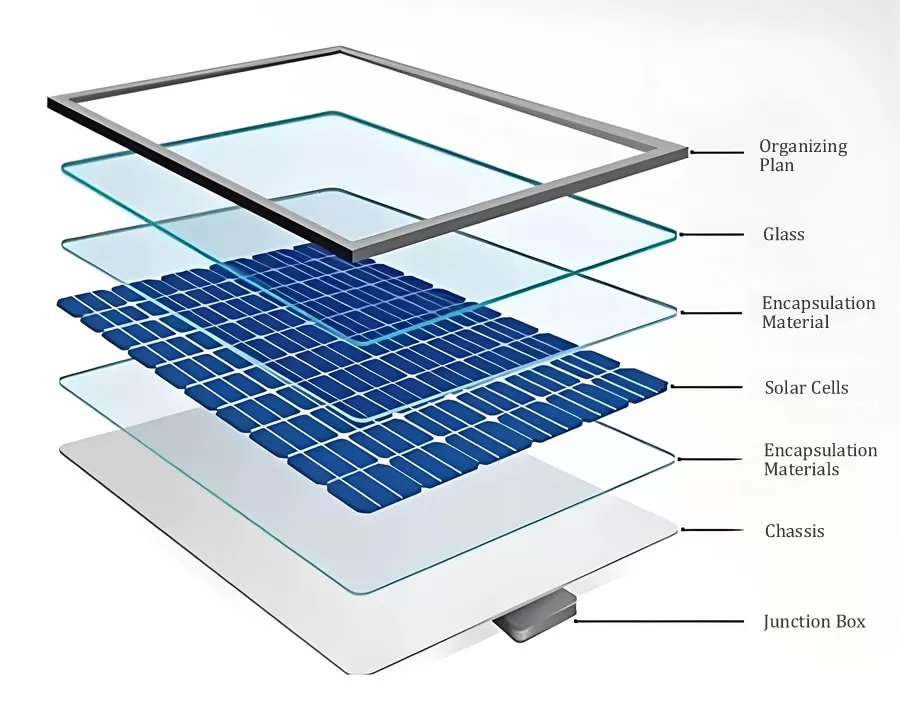

Description of solar photovoltaic cell structure

With the wide application of solar photovoltaic systems, in more and more photovoltaic projects, businessmen begin to mean how to improve the conversion of photovoltaic systems. The conversion of solar photovoltaic systems involves many factors, such as sufficient sunlight, the conversion rate of solar panels, as well as the storage efficiency of PV energy storage systems, etc. Brice Solar shows how to improve the conversion rate of solar energy, the core technology of the solar battery in detail to understand.

Ⅰ. The core technology analysis of solar cells

1. The battery photoelectric conversion technology

The core principle of solar cells is based on the photovoltaic effect, that is, the semiconductor material absorbs photons and excites the electron-hole pairs, forming a current under the action of the built-in electric field in the p-n junction. Currently, the mainstream crystalline silicon cells (e.g. monocrystalline silicon, polycrystalline silicon, etc.) can increase the photovoltaic conversion efficiency to 18%-24% by optimizing the purity and lattice structure of the silicon wafers. Amorphous silicon thin-film batteries reduce energy consumption by simplifying the process to achieve power generation under low-light conditions.

2、Photovoltaic cell material technology

Crystalline silicon materials: occupying more than 90% of the market share, monocrystalline silicon has become the mainstream due to higher purity and efficiency, and polysilicon to meet the low-end demand for low-cost advantage.

Calcitonite materials: with thin, high light absorption coefficient and low-cost potential, such as Toppan has been in mass production experiments to improve the efficiency of the calcitonite battery, and supporting the research and development of TCO conductive glass and other key auxiliary materials.

Multi-junction stacking technology: through different semiconductor layers to absorb the full spectrum of light waves, to achieve higher conversion efficiency (such as laboratory efficiency of more than 30%).

3、Battery structure optimization technology

PERC technology: through the backside passivation to reduce carrier composite, enhance the battery efficiency of about 1-2%, for the current mainstream process.

TOPCon technology: the use of ultra-thin silicon oxide and phosphorus doped polysilicon layer passivation contact, the efficiency of up to 25% or more, and compatible with the existing PERC production line upgrade.

HJT heterojunction technology: combining amorphous silicon and crystalline silicon advantages, double-sided power generation efficiency of more than 24%, but requires a dedicated production line.

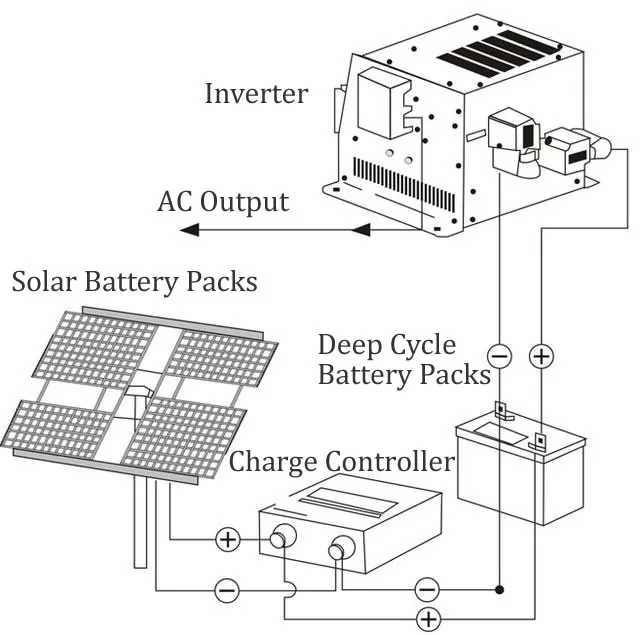

Solar Controller Schematic Diagram

4. panel encapsulation and manufacturing process

Panel encapsulation technology: EVA film, tempered glass and aluminum alloy frame are used to achieve waterproof, pressure resistance and weather resistance, for example, the service life of crystalline silicon modules can reach 25 years.

Welding technology: For example, Dongtai JA has developed the “PV Panel Welding Fixture”, which improves the accuracy of the cell gap through precise structural design, and reduces welding offset and warpage.

5、Typical cases and application direction

Top Solar Calcium Titanium Ore Battery: In Xi'an R&D Industrial Park, Shaanxi Province, China, the company promotes mass-production experiments, and combines TCO conductive glass technology with the layout of next-generation high-efficiency photovoltaic modules.

JA Solar Manufacturing Upgrade: Optimizing production yields through welding fixture patents to meet the PV market's demand for high-precision, low-cost modules.

Solar cell technology is moving toward high efficiency, low cost, lightweight direction, the breakthrough of chalcogenide and stacked layer technology will further promote the iteration of the PV industry.

Integrated house project photovoltaic panels and racking used in BIPV projects

Ⅱ. Solar photovoltaic system conversion rate improvement program

1. Preferred high-efficiency battery modules

Monocrystalline silicon PERC/TOPCon technology: the use of backside passivation (PERC) or tunneling through the oxide layer passivation contact (TOPCon) structure, mass production efficiency of up to 24% -25%, and compatible with the existing production line upgrade.

Chalcogenide stacked cell: Through the combination of wide bandgap chalcogenide layer and narrow bandgap crystalline silicon layer, the spectral absorption range is extended to 300-1200nm, and the laboratory efficiency exceeds 33%.

2. Precise installation and system design

Intelligent tracking system: Equipped with dual-axis solar tracking bracket, real-time adjustment of module inclination angle through photosensitive sensors, annual power generation increased by 10%-25%.

Shadow Avoidance Design: 3D modeling by UAV is used to analyze the surrounding environment to ensure that the module spacing is ≥1.5 times the height of the modules, reducing the loss of shading between arrays.

3. Intelligent operation and maintenance system integration

Multi-parameter sensor network: deploy temperature and humidity, irradiance and dust monitoring modules to provide real-time feedback of environmental data to the central control system.

AI-driven optimization algorithm: Machine learning-based MPPT (Maximum Power Point Tracking) technology dynamically adjusts the inverter operating voltage with millisecond response speed.

4. Enhanced thermal management and packaging

High-efficiency heat dissipation material: adopting graphene thermal conductive backsheet, for every 10℃ reduction in module operating temperature, the output power is increased by 0.5%.

High-barrier encapsulation process: using POE film instead of EVA film, the water vapor transmission rate is <0.1g/㎡-day, slowing down the efficiency degradation caused by the PID effect.

5. Full-cycle performance monitoring

Laser source IPCE test: Monthly test equipment with wavelength accuracy ±0.1nm is used to detect fluctuations in photoelectric conversion efficiency and locate faulty components.

Digital Twin Maintenance: Construct a component decay model to predict efficiency changes over a 25-year lifecycle and formulate a preventive cleaning/replacement plan.

Photovoltaic and Energy Storage Stations

Implementation Case Reference

Bifacial module + tracking system: Matching bifacial power generation module (bifacial rate ≥80%) with single-axis tracking bracket, the measured power generation of desert power station is increased by 35%.

Calcite-Crystalline Silicon Stacking Demonstration Project: 29.8% average daily conversion efficiency was realized in the Qinghai test base in China, which is 46% higher than that of traditional modules.

Through the integration of the above technologies, the overall efficiency of PV systems can be increased by 30%-50%, and the payback period can be shortened to 4-6 years.

Therefore, to improve the conversion rate of solar PV system, we can from the PV system infrastructure, the selection of solar panels, the use of preliminary considerations, from the core technology, and then to the integration of the entire PV system, the overall improvement of the conversion rate of the PV system.

One step to find us,we will respond within 24 hours.

More Contact Details

008613738639386

[email protected]